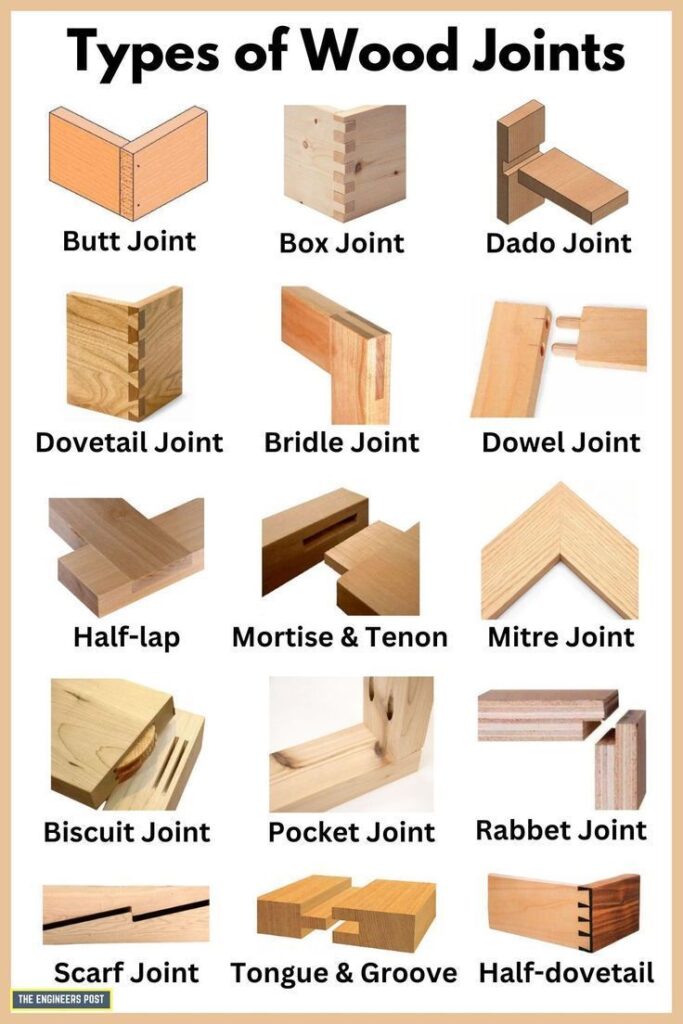

Understanding wood joinery is fundamental to building strong, durable, and professional-looking wooden structures. Whether you’re crafting furniture, cabinets, or frames, choosing the right joint makes all the difference. Here’s a detailed breakdown of the most commonly used wood joints every woodworker should know:

1. Butt Joint

The simplest of all joints. It involves joining two square-cut pieces of wood by simply butting them together, usually fastened with nails, screws, or glue. It’s quick but not very strong on its own.

2. Box Joint (Finger Joint)

A strong corner joint where interlocking fingers are cut into the ends of two pieces and glued together. Often used in boxes and drawers for its strength and decorative appeal.

3. Dado Joint

A slot (or groove) is cut across the grain of one board, into which another board fits. Commonly used in shelving and cabinetry to hold horizontal pieces firmly in place.

4. Dovetail Joint

Known for its incredible strength and resistance to being pulled apart, this joint features wedge-shaped “tails” and “pins” that interlock. A hallmark of fine craftsmanship, especially in drawers and heirloom furniture.

5. Bridle Joint

Similar to a mortise and tenon, but with an open-ended design. The end of one piece is cut to fit into a slot in the other. Strong and ideal for frames and structural assemblies.

6. Dowel Joint

Uses wooden pegs (dowels) inserted into aligned holes in both pieces of wood. Great for creating a strong joint without visible hardware, commonly used in furniture assembly.

7. Half-lap Joint

Each board is cut halfway through its thickness so they overlap evenly. Offers a strong, flush fit and is often used in framing and cross members.

8. Mortise & Tenon Joint

One of the oldest and strongest joints. A rectangular “tenon” on one piece fits snugly into a matching “mortise” hole in another. Perfect for doors, tables, and heavy load-bearing frames.

9. Mitre Joint

Created by cutting two boards at a 45° angle and joining them to form a 90° corner. Common in picture frames, moldings, and trim where clean lines are essential. Often reinforced for strength.

10. Biscuit Joint

Uses a football-shaped compressed wooden “biscuit” that fits into matching slots on both boards. When glued, it expands and locks the pieces together. Great for aligning boards during edge joining.

11. Pocket Joint

Uses screws driven at an angle through a pre-drilled pocket hole. Quick, easy, and strong—ideal for cabinets and face frames.

12. Rabbet Joint

A recess or step is cut along the edge of one board, allowing another piece to fit into it. Frequently used in the back panels of cabinets or drawers.

13. Scarf Joint

Joins two pieces end-to-end with a tapered or angled cut to increase surface area for glue. Commonly used when longer boards are needed but only shorter stock is available.

14. Tongue & Groove Joint

One board has a protruding “tongue” that fits into a corresponding “groove” on the other. Common in flooring, paneling, and table tops for smooth alignment and added strength.

15. Half-dovetail Joint

A simplified version of the full dovetail, where only one side features angled tails. Still offers good mechanical strength and is easier to produce than full dovetails.

16. Pocket Joint

(Appears again for emphasis) Popular in modern woodworking due to the speed and simplicity of joining pieces with angled screws. Best when the joint won’t be visible.

💡 Conclusion

Whether you’re building a simple box or crafting a fine cabinet, the right joint can elevate your work from ordinary to exceptional. Save this guide and refer back any time you start a new project!